Industry knowledge

1. Proper Installation:

- Ensure the ice maker is installed on a level surface with proper ventilation to prevent overheating.

- Follow the manufacturer's installation guidelines, including electrical and water connections.

- Make sure the ice machine is properly grounded to prevent electrical issues.

2. Regular Cleaning:

- Clean the ice machine's components, including the evaporator coils, ice bin, and water distribution system, on a regular basis.

- Remove mineral deposits, scale, and debris that can affect performance and ice quality.

3. Water Filtration:

- Use a water filtration system to maintain water quality and prevent mineral buildup.

- Replace water filters according to the manufacturer's recommendations.

4. Routine Maintenance:

- Schedule regular maintenance according to the manufacturer's guidelines or recommendations.

- Have qualified technicians inspect and service the machine to identify potential issues early.

5. Water Level Monitoring:

- Ensure a consistent water supply to the ice machine to prevent interruptions in ice production.

- Monitor water levels to prevent the machine from running dry, which could damage components.

6. Temperature Control:

- Maintain proper operating temperatures to ensure efficient ice production and prevent excessive wear on components.

7. Proper Ice Usage:

- Educate staff on responsible ice usage, avoiding overloading the ice bin or exposing it to extreme temperature changes.

8. Energy Efficiency:

- Opt for energy-saving modes during off-peak hours to reduce energy consumption.

- Ensure the machine is properly insulated to minimize energy wastage.

9. Prompt Repairs:**

- Address any malfunctions or issues promptly to prevent small problems from escalating.

- Keep spare parts on hand to minimize downtime in case of component failure.

10. Emergency Procedures:

- Train staff on emergency shutdown procedures to prevent damage in case of sudden issues.

- Have a plan in place for addressing power outages or equipment failures.

11. User Training:

- Train staff on how to use and maintain the ice machine properly.

- Provide guidelines on cleaning procedures, filtration system maintenance, and best practices.

12. Monitor Ice Quality:

- Regularly check the quality of the ice produced to ensure it meets food safety standards and customer expectations.

13. Document Procedures:

- Create and maintain a manual that outlines proper operation, maintenance, and troubleshooting procedures for the specific machine model.

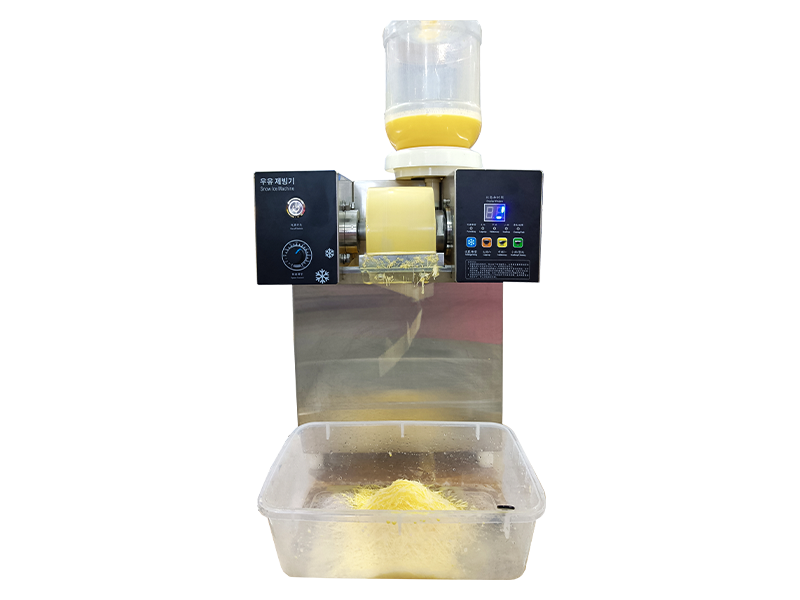

By following these steps, you can ensure that your crushed ice maker machine operates smoothly, reliably, and efficiently in the food industry, contributing to consistent ice production and overall operational success.

English

English Español

Español