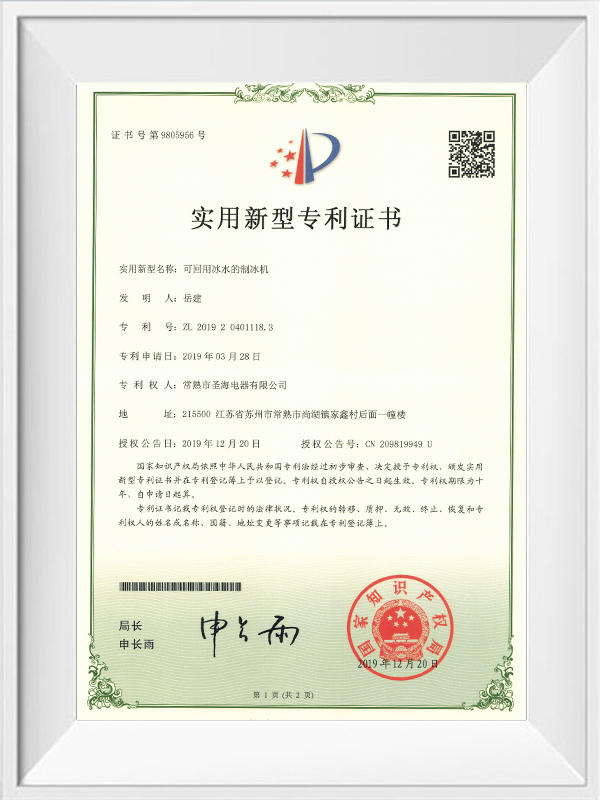

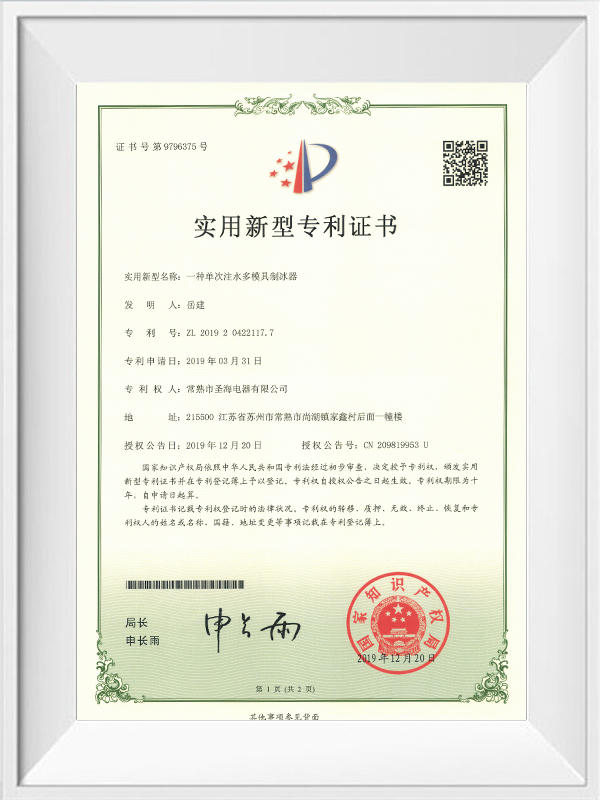

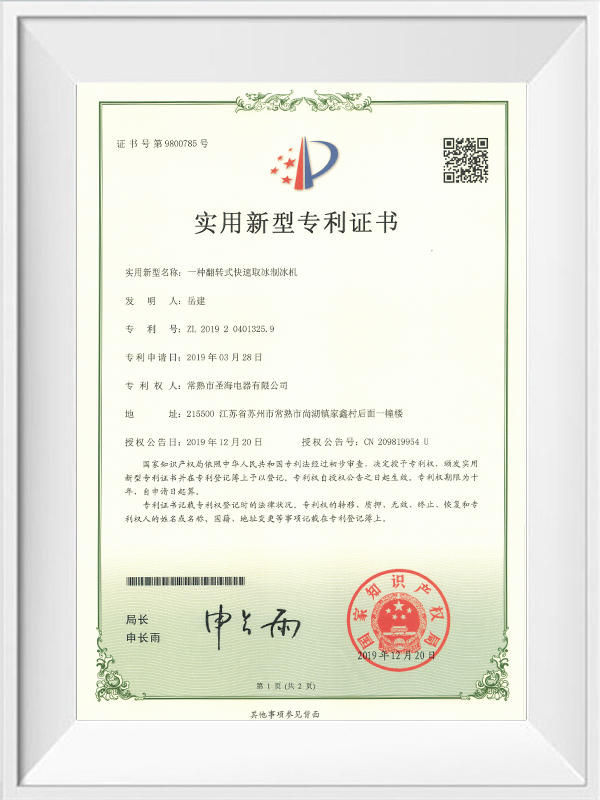

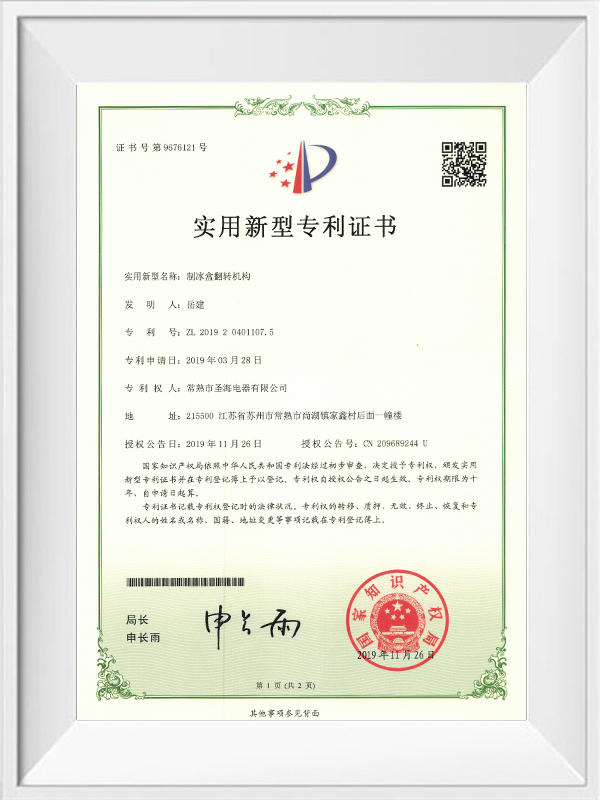

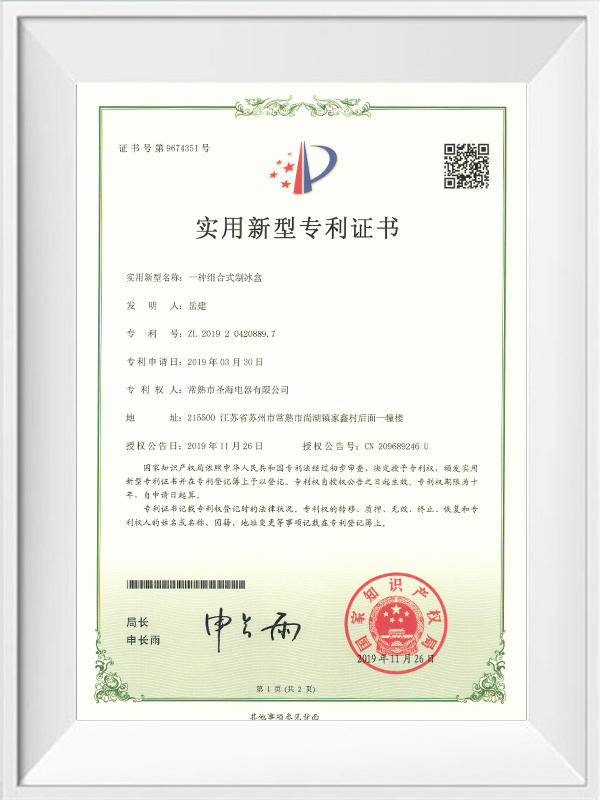

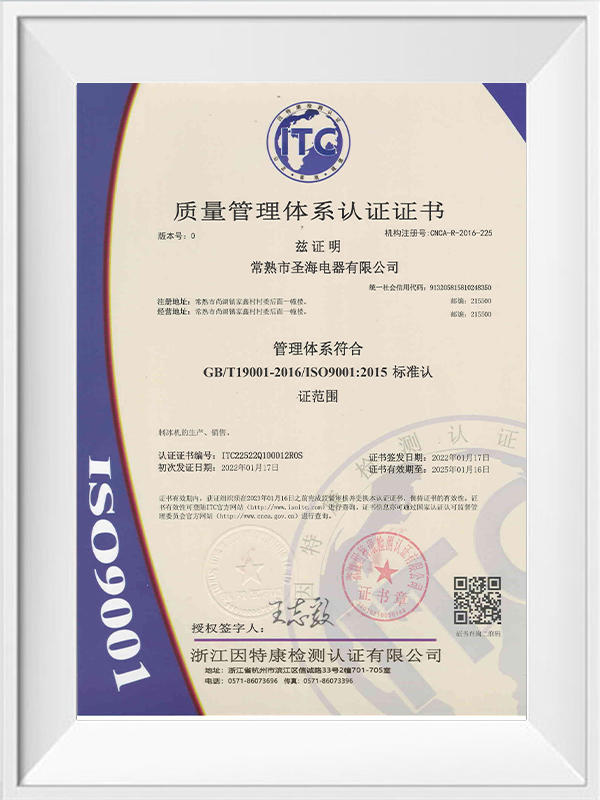

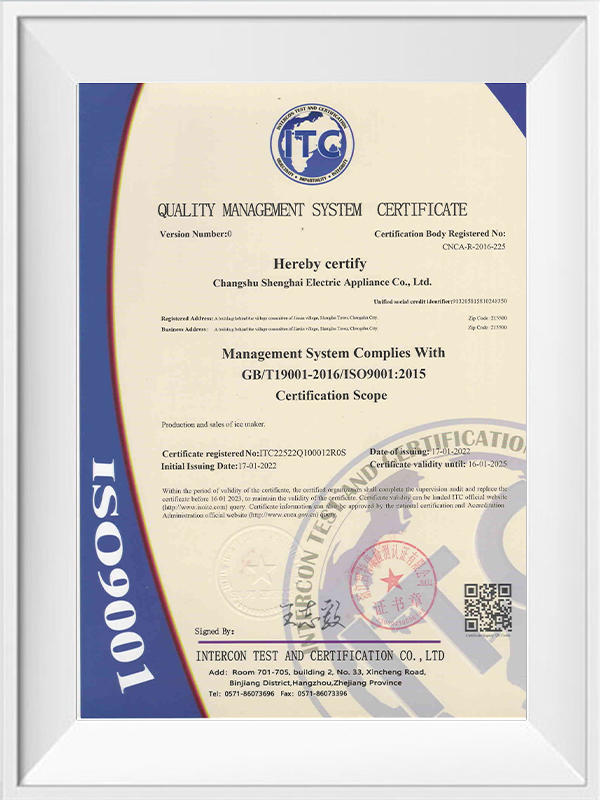

Shenghai has been adhering to the business philosophy of innovation for development, constantly developing new products independently and independently, and has obtained a number of national product patents in recent years.

NEXT

The Structure of Milk Cooler

A milk cooler is a type of refrigeration system that is specifically designed to cool and store milk. The exact structure of a milk cooler may vary depending on its size, capacity, and intended use, but the basic components of a typical milk cooler include:

Insulated cabinet: The main body of the milk cooler is an insulated cabinet that is designed to keep the milk at a consistent temperature. The cabinet is typically made of durable, food-grade materials like stainless steel or high-density polyethylene.

Compressor: The compressor is the heart of the refrigeration system and is responsible for circulating refrigerant through the system. The compressor typically sits at the bottom of the milk cooler and is powered by electricity.

Condenser: The condenser is a heat exchanger that is responsible for releasing heat from the refrigerant. It is typically located on the back or side of the milk cooler and is cooled by a fan.

Evaporator: The evaporator is another heat exchanger that is responsible for absorbing heat from the milk. It is located inside the milk cooler and is cooled by the refrigerant.

Expansion valve: The expansion valve is a small component that regulates the flow of refrigerant into the evaporator. It is typically located near the evaporator and is controlled by the thermostat.

Thermostat: The thermostat is a temperature control device that is responsible for regulating the temperature inside the milk cooler. It typically sits at the top of the milk cooler and is connected to the expansion valve.

Milk containers: The milk containers are the storage compartments inside the milk cooler where the milk is kept. They are typically made of food-grade materials like stainless steel or plastic and are designed to hold the milk at a consistent temperature.

Overall, the structure of a milk cooler is designed to maintain a consistent temperature inside the cabinet and ensure that the milk remains fresh and safe for consumption.

The Classification of Milk Cooler

Milk coolers can be classified based on different criteria, including:

Type of Cooling:

Capacity:

Cooling Method:

Mobility:

Material:

The classification of milk coolers can vary depending on the manufacturer and region, but these are some of the most common criteria used to classify them.

A cube ice machine’s ability to handle variations in water temperature and quality is crucial for maintaining consistent ice production. Here’s how these machines typically manage ...

The crescent shape of ice in a crescent ice machine is achieved through a combination of specialized molds and a precise freezing process. Here’s a detailed explanation of how this...

Bullet-shaped ice, produced by bullet ice makers, has several distinctive features that affect its melting rate and cooling efficiency. Here’s an analysis of the advantages and dis...

Bullet ice makers are widely used in both residential and commercial settings for their efficiency, versatility, and ease of use. Here are some of the standard features typically f...