Industry knowledge

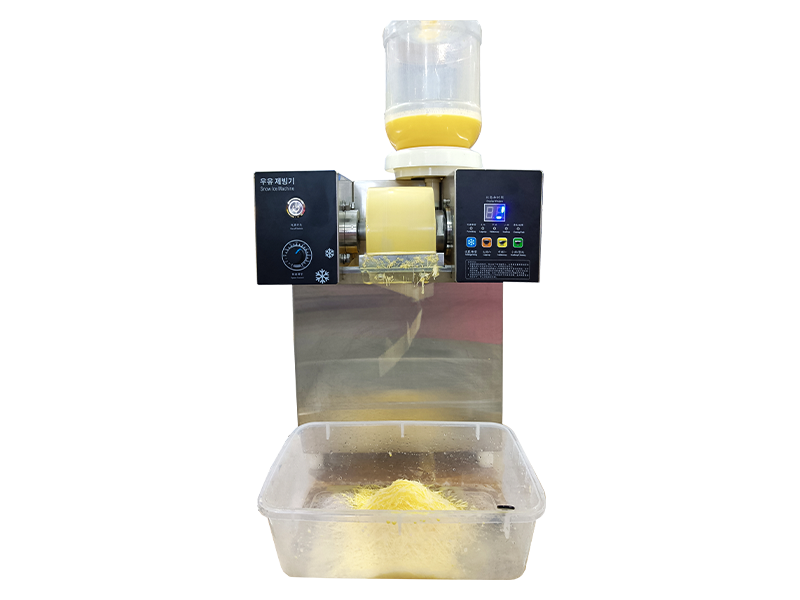

1. Sensor Integration: Automated machines like ice machines are equipped with various sensors to monitor different parameters. These sensors might measure temperature, pressure, humidity, voltage, current, etc. The first step is to integrate these sensors into the machine's control system.

2. Data Acquisition: The sensors continuously gather data related to the machine's operation. This data is typically collected at regular intervals and transmitted to a central processing unit for analysis.

3. Data Preprocessing: Raw sensor data can be noisy or contain outliers. Preprocessing techniques, such as filtering and data smoothing, are applied to ensure that the data is accurate and reliable.

4. Feature Extraction: Relevant features are extracted from the preprocessed data. These features are characteristics that can help identify the machine's operating state and potential faults. For an ice machine, features could include ice production rate, compressor speed, water temperature, etc.

5. Baseline Model: A baseline model is created using historical data. This model represents the normal operating behavior of the machine. It's trained to recognize patterns in the data that indicate everything is functioning properly.

6. Anomaly Detection: Any deviations from the baseline model are considered anomalies. Anomaly detection algorithms, such as statistical methods (z-score, Mahalanobis distance) or machine learning techniques (Isolation Forest, Autoencoders), are applied to identify these anomalies.

7. Thresholds and Alarms: Anomalies that surpass predefined thresholds trigger alarms or notifications. These thresholds are set based on the acceptable range of behavior for the machine. Depending on the severity of the anomaly, different levels of alarms might be generated.

8. Fault Diagnosis: When an anomaly is detected, the system may provide additional information to help diagnose the issue. This could include the specific sensor readings that triggered the alarm and potential reasons for the anomaly.

9. Maintenance and Reporting: The system can log the detected anomalies, actions taken, and their resolutions. This data can be used for future analysis, maintenance scheduling, and performance optimization.

10. Continuous Improvement: Over time, the system can learn from the detected anomalies and their outcomes. This information can be used to refine the anomaly detection algorithms and improve the overall fault detection process.

English

English Español

Español